Goldcorp is seeking to expand its presence on many fronts in northwestern Ontario.

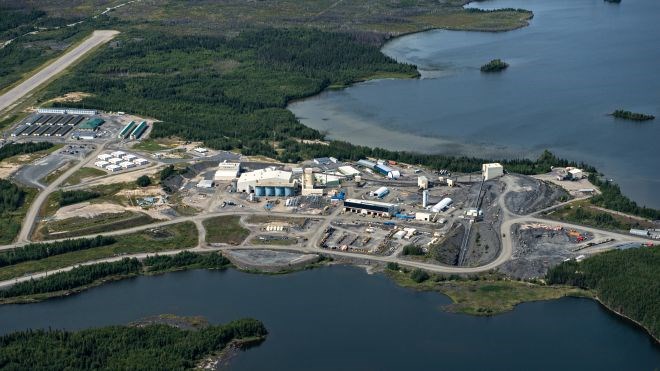

The Vancouver-based gold miner is on course to boost production to greater heights at its remote Musselwhite Mine, 480 kilometres north of Thunder Bay.

Gold production at Musselwhite in 2017 is pegged at 265,000 ounces annually, but with new mine manager Peter Gula at the helm, the company is making moves toward reaching 300,000 ounces.

Originally built by Placer Dome, Musselwhite is a fly-in/fly-out operation for its 530 employees who work on a rotational basis from communities across Canada. About 220 contractors are at the site to work on the new Materials Handing Project.

In a perfect world, mine engineers and geologists want a deposit that’s vertically dipping in order to place a shaft beside it and access it on various drifts and levels to mine it.

The deposit at Musselwhite has about a 20-degree plunge, down to 1,200 metres under Lake Opapimiskan.

“Musselwhite is not very deep but the ore body plunges away from the portal,” said Gula. “We’re not a shaft mine.”

Getting ore to surface takes a long time. Goldcrop is out to quicken it by installing an inner shaft between levels, called a winze, to dramatically cut truck haul times to the mine’s underground crusher.

“Every day that we advance, we’re further than we were yesterday,” said Gula.

The underground truck haul distance to the crusher at the 400-metre level is 7.5 kilometres, about an hour to an hour-and-half round trip for the company’s 17, 40-tonne haul trucks.

The new Material Handling Project, now under construction, is expected to reduce their reliance on trucking those distances while increasing production by 20 per cent.

“We’re going to go from an hour-and-half to about 15 minutes. We can park probably eight to ten trucks,” said Gula.

Down the road, Goldcorp is looking at adopting autonomous trucks running remotely on their own, which should reduce ventilation costs.

North Bay mine contractors Redpath are handling the $90-million project, which got underway last October and is nearing the 25 per cent mark of completion. Work is scheduled to be done by the fourth quarter of 2018.

Daily production should increase from 3,400 tonnes to 4,300 tonnes when finished.

“We’ve got to look for ways to increase productivity and lower our costs,” Gula said.

Only a few years ago, Musselwhite was running between $1,000 and $1,200 an ounce for its all-in sustaining costs. As a keen adopter of new technology, Musselwhite is one of the company’s lowest cost producers and is on track to be a $721 an ounce sustaining costs this year.

They’ve realized a 75 per cent improvement in their mucking activity through the adoption of tele-remote mining from surface, which shaves off two hours in the workday for the development miner.

Gula said that cost-savings profile only stands to improve with the Materials Handling system. Once operating, it will contribute to lowering their sustaining costs to $80 an ounce.

“It’s about looking for ways to improve and continuing to go further, but cheaper.”

In looking to add mine life, the company is aggressively exploring on their large high-prospective claim holdings.

The known ore body plunges to the north, which the company is confident will keep rewarding them for quite some time.”

Gula said they’ve taken a new view to exploration to focus on what’s unknown and if there’s mineral potential closer to the mine’s existing infrastructure, especially to the east and west.

“We’re also looking to step back to look at our exploration profile and see if there’s opportunity to bring in more (ore) around us.”

In Thunder Bay, Goldcorp has taken on greater visibility by emigrating from a cramped satellite office in the city’s south end to more centrally located 4,200-square-foot space in the Inner City area.

Instead of flying administrative personnel to the mine on a rotational basis, these employees will now be based in Thunder Bay, said Gula.

“From a cost savings perspective: you don’t have to fly people in, you don’t have to house and feed them. It’s quite substantial when you add it up.”

Technology is advancing to the point where it’s conceivable that a multitude of duties might be performed at a distance in the near future, added Gula, in referencing two tele-remote surface chairs to run underground equipment.

“Some of that technology could be moved to Thunder Bay – down the road – and we won’t have to pay a premium for people to move onto the site.”

Currently, close to 30 per cent of Musselwhite’s workforce resides in Thunder Bay, a number the company would to enhance to cut down on travel expenses from employees commuting from afar.

Instead of being a hub, Goldcorp wants to promote Thunder Bay as a home for the company.

“We’re starting to promote that and get more involved in the community,” said Gula.

The company is seeking to do more on a philanthropic level in supporting local causes and events like co-sponsoring the Under-18 Baseball World Cup in Thunder Bay next fall.

Gula said he’s arranging partnership-oriented meetings with institutions like Lakehead University and its engineering and geology faculties in looking to have access to a talent pool of young graduates.

“Five or ten years down the road, there’s going to be a shortage of good engineers.