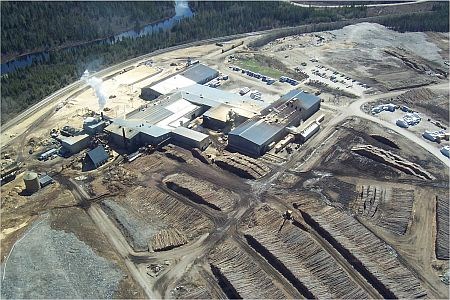

Momentum is building toward re-starting a dormant White River sawmill and expanding it with wood pellet technology and value-added products.

White River Forest Products, the new owners of the former Domtar mill are hopeful of securing the Crown fibre supply necessary to press ahead with a $90-million project that would also see an existing co-generation plant powered up from 7.5 megawatts to 20.

“We're working closely with (Ministry of Northern Development, Mines and Forestry) to have the license transferred to White River Forest Products,” said company president Jeff Butler.

With Ontario's wood supply competition underway and 11-million cubic metres of unused Crown wood now in play, many mill managers preparing applications are tight-lipped in talking to the media as per government rules.

“Once the fibre supply is transferred that will trigger a lot of other positive things,” said Butler.

The wood supply attached to the mill, drawn mainly from the White River management unit, is 568,000-cubic metres, according to the Ministry Recognized Operating Level when Domtar was operating it.

“Long-term we would need more for what we want to do,” said Butler.

Project financing would come from a combination of private and public funding. Some former Domtar employees have come forward offering a repayable loan to help get the operation re-started. It all hinges on the wood supply being secured.

“The (wood) feedstock and markets are key here,” said Butler.

The plan is to fire up the sawmill, expand the co-gen to produce heat and power, add wood pellet technology and launch some value-added forest products.

Butler was reluctant to disclose what those would be.

“We're discussing products with different marketing agencies.”

Butler said there is possible “synergies” with Haavaldsrud Timber Company, a sawmill in nearby Hornepayne.

“From a forest management perspective on the license (application), we're working with them.”

The power would be sold to the Ontario grid and the heat would be used for a proposed district heating plan in the community of 840. “We're doing pre-engineering right now,” said Butler. “We have an existing study and we're talking with the Federation of Canadian Municipalities about their green municipal fund. There's a lot of positive things going on.”

The company is working with the Ontario Power Authority on a power of sale agreement which involved the government's wood supply competition to access fibre for the co-gen plant.

Some mill modifications would have to be done to accommodate the wood pelletizing equipment. Butler said he has some preliminary quotes for the machinery.

The White River mill has been in cold storage since 2007 when Domtar closed the laid off 236 employees. Butler wants to fire up the operation this year.

“We don't want the mill to be shut down another winter.”

This new venture would employ 200 workers, both in mill and woodland operations.

Butler said some former mill employees have stayed in the area, while others have scattered, still he is fielding phone calls from worker wanting to come back.

Management has been working with the local labour adjustment committee and the Ontario government to put together a training program and allow some potential workers to attain their Grade 12 equivalency.

“We're trying to address some of the social issues,” said Butler. “The community needs revenue and families are separated.”

The new owners are a three-way partnership between the Town of White River's economic development department, the Pic Mobert First Nation and Butler, a northwestern Ontario industry veteran who runs a forestry consulting business in southern Ontario.

www.whiteriver.ca

www.butler-consultants.ca