For Nortek Computers, it always helps to have an edge.

The 25-employee North Bay technology company has made its mark retrieving lost data from people's crippled hard drives. Now it has a new specialty.

Last fall, they launched a new service to repair and refurbish high resolution flat panel display monitors for the global aviation industry, specifically the screens used by air traffic controllers.

They bill it as a cheaper way to extend the life of these high-end monitors used in aviation, military and industrial applications.

Since 2001, national aviation associations around the world have been replacing their old television screen-style CRT (cathode ray tube) monitors with LCDs (liquid crystal displays).

After about eight years of constantly running, or 40,000 hours, these monitors start to deteriorate. The cold cathode florescent lamps (CCFL) eventually start to burn out and there are no replacements available anywhere in the marketplace.

"As they come up to that time, they're all failing," says Troy Prior, Nortek's support service manager. "That's our opportunity."

To buy a brand new monitor costs between $35,000 and $50,000.

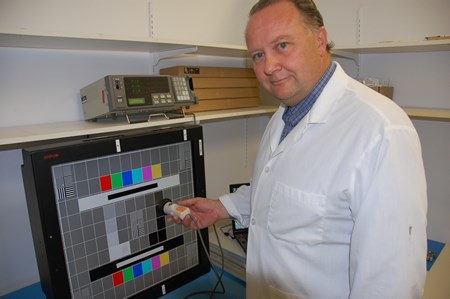

For less than five per cent of buying a new one, Nortek refits and recalibrates them with new bulbs and balances the light to ensure there are no dark patches across the screen.

This new line of work started with one of their customers, aerospace manufacturing giant Lockheed Martin. Nortek was handling their tape drive repairs and Lockheed asked if they did LCD monitor work.

Never turning an opportunity to please a big customer, Nortek president Bob Everest obliged.

But it was a problem to source new CCFL tubes because the existing OEM (original equipment manufacturer) wouldn't sell any to Nortek, so they had to engineer a solution.

Like most big industries, the aviation sector uses OEMs to make individual components under a main company brand name.

The OEM made a specific voltage for themselves and wouldn't release that, so Nortek technicians had to retrofit another bulb with the exact specifications.

"Because these automatically adjust for intensity across the entire panel, we had to determine and pinpoint the algorithms within their software," says Everest.

It was no easy task to figure it all out. Of the four trays of bulbs inside a display panel, each tray has individual electronics tuned separately because each bulb is a little different, says Prior.

"Our job was to duplicate the OEM (original equipment manufacturer) process."

There's a reason Nortek went to so much trouble to figure it all out. Because there is an extremely huge global market from aviation associations in the U.S., China, Britain, Italy, Russia and the former Eastern Bloc countries.

With Lockheed Martin's blessing last October, the company has handled about 200 monitors. Now Everest wants to promote their high-end monitor repair and refurbishment business to the mining, oil and gas, and medical sectors.