Andrew Kostuik is standing in NORCAT’s delivery bay, eyeing a load of discarded electrical components — a weathered control panel, metal levers and a tangled nest of hydraulic lines — just hauled in from Toronto.

The centrepiece of the delivery is a decommissioned lift bucket — the kind used by utility crews to elevate workers high above the street — now destined for its second life as a model in a virtual training simulator.

The electrician who delivered the gear, a member of the International Brotherhood of Electrical Workers (IBEW), walks Kostuik through each lever, grip and toggle switch, and says he hopes this old equipment is put to good use.

For Kostuik, NORCAT’s studio director, the delivery is more than just a drop-off of scrap — it’s a key step in the development of his team’s hyper-realistic motion capture training program, part of a broader partnership with the National Electrical Trade Council (NETCO).

In the coming days, this beat-up gear will be wired into NORCAT’s mixed-reality lab, letting apprentices learn to operate a bucket truck without ever leaving the ground.

“This is the real deal,” Kostuik said. “We’ve never converted something like this before — there’ll be challenges — but that’s what makes it exciting.”

The bucket truck simulator is just one of several training tools taking shape inside NORCAT’s new motion capture studio — the “Mo Cap”, Kostuik calls it — a first-of-its-kind facility in Northern Ontario.

Built in partnership with NETCO, the studio uses high-fidelity motion tracking and an AI-driven digital approach to create immersive, hands-on learning experiences for tradespeople.

For electrical workers, it means practising complex, high-risk tasks in a controlled environment — from pulling cable through a conduit to manoeuvring heavy equipment — before ever setting foot on the job site.

“We’re giving learners the chance to make mistakes, experiment, and see the consequences without putting themselves or anyone else in harm’s way,” Kostuik said. “That extra experience builds confidence — and that’s huge for the industry.”

Similar training approaches have been used in mining, aviation, and emergency response, Kostuik said. At NORCAT, that’s meant developing underground vehicle inspections for miners and augmented reality fire extinguisher training used by clients ranging from the U.S. Space Force to major airlines.

Now, it’s tackling some of the tough environments faced by electrical workers.

“We’re trying to figure out where the gaps are in any industry,” Kostuik said. “If we don’t have a crane [on the training premises], how can VR simulate that crane, give you that experience?

“You’re really benefiting the learner; you’re building that muscle memory at the end of the day.”

But what makes the Mo Cap Studio unique, Kostuik said, is its ability to capture every movement and expression in fine detail, then feed that data into training scenarios that feel almost true to life.

“Everybody laughs at the little details we do … like putting a Tim Hortons cup in there, a Nutri-Grain bar or something,” Kostuik said. “You see those details, and you’re grounding yourself in that experience.

“Those little cues help make you feel like you’re super immersed — like this is believable. And then the more you can do that, the more they retain their knowledge.”

It’s part of what he calls “the sandbox” approach. It’s a playful, experiential way of testing, revising and then retesting a product.

“It’s for them to learn and to prove that you can do it,” he said. “You’re saving on materials, which is a bonus, but they can also make poor choices and see the repercussions without putting anyone in harm’s way.”

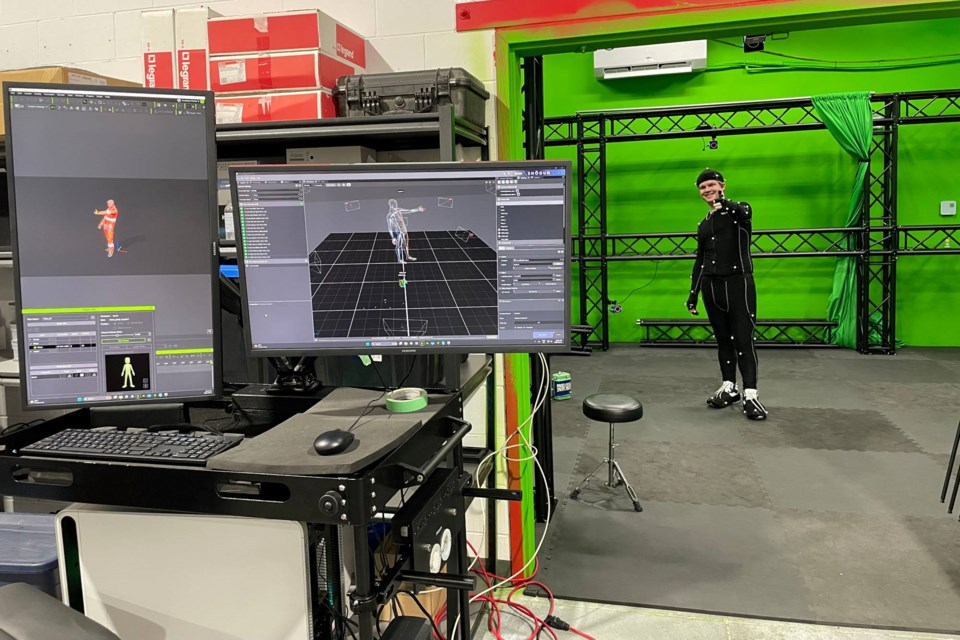

Stepping inside the Mo Cap studio feels like you’ve wandered onto a high-tech Hollywood backlot. Bright green walls — the same chroma key backdrop used for blockbuster visual effects — a network of black trusses and 16 Vicon precision cameras, each aimed to track the tiniest movement.

On the floor, a technician in a black body suit dotted with reflective markers swings a tool, while in a nearby room a bank of computers transform those motions into an animated digital avatar in real time.

“It’s recording every little detail that I’m doing, even my breath and facial expressions,” Kostuik said. “Now, when you’re engaging with that avatar and the environment, you’re more emotionally connected to it.”

Later, details will be added to the environment — the avatar will soon be clothed in high-vis worker’s gear, or they’ll add a helmet, and tools of the trade can be imported onto the platform as needed.

He credits much of the studio’s success to the tight-knit group behind the technology.

“We’ve got a really lean and talented team that come up with some really interesting solutions to things,” he said.

They’ve become so adept at tackling tough problems and fixing things in the fast-paced lab that they are jokingly referred to around the office as “the Dumpster Fire Team.”

“They save the day all the time,” Kostuik said.

The small size, he added, is an advantage.

“This team has a lot of impact on a lot of things that we do … it’s not just this mega, faceless thing … it’s an interconnected web of people pushing this thing forward in every direction.”

For NETCO, partnering with NORCAT meant moving its VR training development out of the U.S. and into Canada — and, more specifically, Northern Ontario.

In recent years, NETCO — a group that develops training standards, promotes skills development, and supports innovation in the electrical industry across Canada — has invested heavily in technologies such as virtual and augmented reality to give apprentices more hands-on experience.

Most of that technology was developed and designed for the U.S., which has slightly different standards and definitions inside the industry.

Kostuik said with NORCAT’s push into the field — not to mention the global recognition for its work — shifting to a local base of operations keeps Canadian dollars at home while proving that world-class training technology can be built here.

“When they found us, they realized that they could do this in their own backyard. They could keep the money here and produce groundbreaking, award-winning work,” Kostuik said.

“We’re proving that we can do it in not only Canada, but Northern Ontario.… We can do it here; we’re getting international recognition for it.”

The work reaches beyond the electrical trades, and Kostuik’s hope is that other fields see its potential.

“Anyone from mining, hands-on skilled trade to police enforcement, law, tactical, military,” Kostuik said.

“It just overlaps in so many different industries. We’ve been hidden for too long, and now we’re getting this recognition. We have built a powerhouse and we want to show people that we can do it right here.”