A Northern Ontario gold mining company is working to set up a newer version of the old Ragged Chutes hydraulic air compressor system that served the silver mines in Cobalt more than 100 years ago.

The federal government has announced an investment of $2.1 million for what it calls a green mining project aimed at developing an alternative to the mechanical air compressors used in underground mining to operate rock drills, small tugger hoists and ore chutes.

A news release from Sudbury MP Paul Lefebvre said the project is being deployed at the Holloway Mine owned by Kirkland Lake Gold and is expected to reduce energy consumption by almost 40 per cent.

Kirkland Lake Gold will use Sudbury-based Electrale Innovation Ltd’s hydraulic air compressor (HAC) technology, which relies on water and gravity to compress air. The cooler, drier, oil-free compressed air will also improve equipment maintenance and reliability at the Holloway Mine, said the news release.

The project is being funded through Natural Resources Canada’s Clean Growth Program. This project is harnessing the HAC technology to bring it to commercial scale in an operational underground mine and to build a new industry standard for compression in applications beyond underground mining, the release said.

The government investment of $2,125,000 is only part of the full cost of $6,959,400.

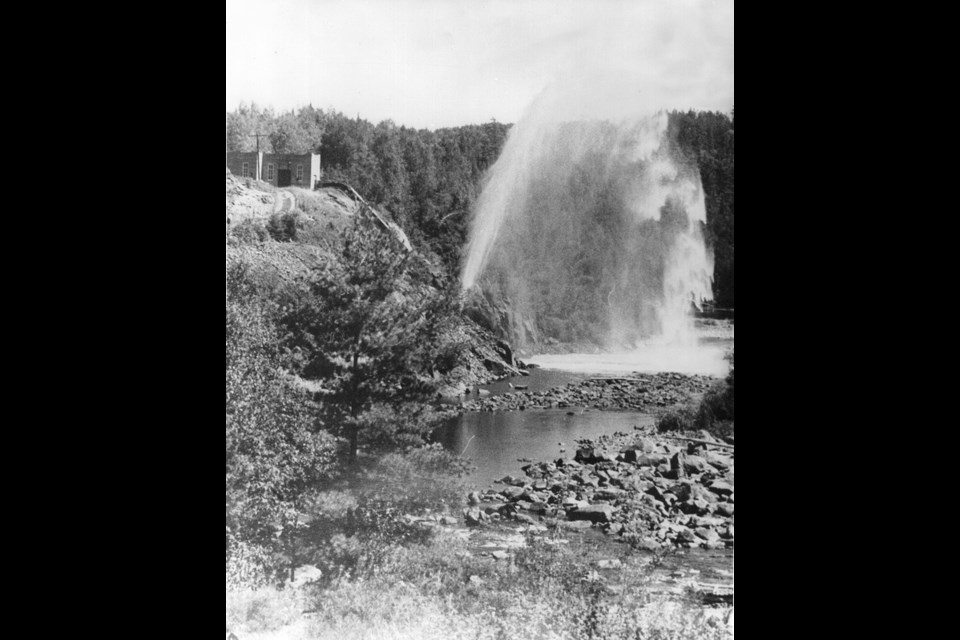

The use of conventional electric-powered air compressors is a significant cost in modern mining operations. The hydraulic compressor, such as the one created at Ragged Chutes, used the force of the Montreal River and gravity to compress the air which was then piped overland to Cobalt mines.

“The Government of Canada continues to invest in projects that are positioning Canada’s mining industry to lead the clean energy future,” said MP Lefebvre, who is also parliamentary secretary to Canada’s minister of natural resources.

"Through strong government partnerships and a commitment to innovation, we are building the sustainable and competitive mining industry of tomorrow."

“Kirkland Lake Gold is delighted to be working with NRCan and the project partners on this hydraulic air compressor deployment,” said Alasdair Federico, executive vice-president of Kirkland Lake Gold.

"By reducing energy consumption without negatively impacting costs and performance, Electrale’s hydraulic air compressor is a perfect fit with our sustainable mining objectives, and we are proud to take a leading role in the commercial deployment of this technology."

This story originally appeared in the Sudbury Mining Solutions Journal.