Norbord Inc. has been fined $65,000 following a guilty plea stemming from a 2018 incident in which a worker was injured at its engineered wood plant in northwestern Ontario.

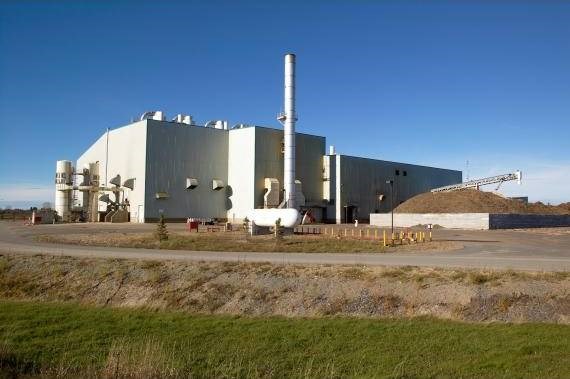

Located in Barwick, 392 kilometres west of Thunder Bay, the Norbord plant produces oriented strand board (OSB), a type of engineered wood product comprised of layers of adhesives and wood strands.

On Oct. 23, 2018, a worker was injured after a machine activated unexpectedly. The Ministry of Labour, Training and Skills Development found that the machine was not equipped with a guard or other device to prevent a worker from accessing hazardous moving parts.

A full ministry account of the incident follows:

The strapping machine is among one of the machines involved in the production of OSB at the mill. The strapping machine is designed to automatically apply strapping to bundles of newly produced OSB prior to their shipment.

Wood packing material known as dunnage as well as edge protectors are also automatically put in place to protect against damage.

A programmable logic controller (PLC) is an industrial digital computer which is used in the manufacturing process. In this case, the PLC controls the automatic function of the strapping machine and its various conveyors. Several sensors ensure that each bundle of OSB, dunnage and edge protectors are in place before the strapping operation occurs.

In automatic mode, the PLC starts the conveyor to move the bundle into the strapping machine. When the sensors signal to the PLC that the bundle is in the correct position, the PLC stops the conveyor. The PLC then energizes a ram to push the dunnage into position under the bundle.

When the dunnage is in the correct position, it contacts something known as the "flop gate" or actuator which has a sensor connected to the PLC. The top portion of the strapping machine (the platen) then hydraulically lowers to compress the bundle; strapping is applied around the bundle, dunnage and edge protectors. The conveyor then moves the bundle forward and the process is repeated for a second strap on the bundle.

On Oct. 23, 2018, the strapping machine was running in automatic mode when it suddenly stopped after moving an OSB bundle into position. A worker approached the front of the machine to investigate and troubleshoot the problem. The worker discovered that an edge protector had fallen and was preventing the movement of the flop gate/actuator. Since the flop gate/actuator wasn't in the expected position, the PLC didn't receive the signal required to proceed further.

The worker bent over to pick up the edge protector from where it had fallen. As soon as the edge protector was removed, the flop gate/actuator moved, which caused the PLC to receive the signal to proceed with the strapping operation. The platen lowered and the worker was caught between the bundle and the platen, suffering an injury.

In addition to the $65,000 fine, Nobord was charged a 25 per cent victim surcharge as required by the Provincial Offences Act, which goes into a provincial government fund to assist victims of crime.

Norbord is owned by Vancouver, B.C.-headquartered West Fraser Timber Co Ltd. The acquisition was completed on Feb. 1.