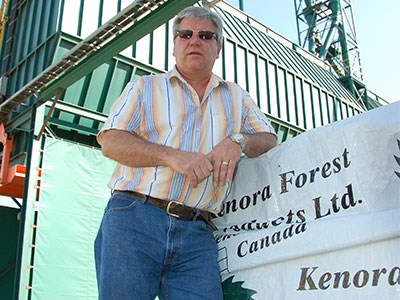

When news leaked out in mid-January that the mothballed Kenora Forest Products stud mill would be back operating by summer, it didn't take long for mill manager Rod McKay to be inundated with job queries.

“The phone has been ringing off the wall.”

After a decade of despair, there is a resurgence happening in the forestry industry with a U.S. homebuilding sector that's trending upward and increasing Asian demand that's boosted lumber prices north of $300 for 1,000 board feet.

“A modest start in housing is creating a market where there's just not enough lumber to go around right now,” said McKay, noting that prices are high enough that no cross-border softwood lumber duty is applied.

At the same time, the ravages of the mountain pine beetle have cut sharply into British Columbia's wood exports to China and Japan, thus opening up an opportunity for Eastern Canadian producers.

“With all the bug kill in the West, there's a good market for wood from this area to go into Japan because it's bright, white, no blue stain, and it really has a high-end appearance grade. We'll be looking at that quite seriously,” said McKay.

With a mill startup plan being drawn up and a new labour collective agreement still to be signed, McKay estimated production could resume, beginning with one shift, sometime between May and July.

Kenora Forest Products has been darkened since April 2008 when the crash of the U.S. housing market caused its Manitoba parent company, Prendiville Industries, to shutter the operation and lay off 105 employees.

It was one of the local casualties during the industry upheaval that saw Kenora lose hundreds of jobs, punctuated by the 2006 shutdown of the since-demolished Abitibi Consolidated pulp and paper plant that put 361 workers on the street.

But Prendiville always expected the mill to reopen when market conditions improved. The heat was kept on in the buildings and production equipment was maintained and periodically fired up.

Still in Prendiville's plans for Kenora is a $30-million capital expansion plan that would boost production capacity from 80 million board feet to 200 million, and could see the mill delve into manufacturing machine-stress related lumber or becoming a random- length or long-length stud mill.

Included in that plan is a joint venture with an undisclosed partner to use wood byproducts, like bark and sawdust, to make a renewable diesel fuel through a special European process.

The company's optimism prompted the Ontario government two years ago to tack on an additional 101,000 cubic metres of Crown wood to the mill's annual allocation of 258,000.

The decade-long gashes to the industry that killed many mills have not only curtailed overall lumber production capacity, but caused many of its experienced workers to find more stable and lucrative jobs in the oil and mining sectors.

“We've

got some people to recall but not very many, so we're going to have

to hire all new people,” said McKay. “We need some people with

sawmill experience.”

On his shopping list are millwrights,

welders, electricians and saw filers with band saw experience.

“I'm hoping it's going to be easier, because Kenora actually is a nice place to live. I have had calls from tradespeople that want to come back here because their family is here and they're living out of town, working in Alberta or Red Lake.”

The restart has Kenora's economic developer officer, Jennifer Findlay, thinking about organizing some job fairs.

“We're working with Kenora Forest Products to coordinate a meeting of all the training, education and employment agencies in the community. They can tell everyone at the same time of their employment needs.”

She agrees with McKay that it's not a difficult sell to recruit tradespeople to work in Kenora, a scenic and very popular recreational and cottage mecca for many Manitobans.

“I know there are people who are commuting in Western Canada who would much prefer to be working here.”

Even with the crushing loss of Abitibi, Findlay's tracking numbers showed only 25 families left the community.

“People have deep roots here. Some began doing other work locally, some started their own businesses or families have stayed here.

“When people ask will we have a workforce for (Kenora Forest Products), we know we're a community where people will move to.”

Findlay said the signs that forestry is making comeback are evident in the community.

The Weyerhaeuser laminated strand board plant celebrated its 10th anniversary last October and the former Abitibi mill property was bought by a Winnipeg developer and is home to a modular homebuilder, a telephone pole peeling plant and a small-scale sawmill with other value-added forest products tenants sure to come.