Mike Campigotto concedes it can be easy to label SafeSight Exploration a drone company.

Since it came on the Northern Ontario mining scene in 2016, its drones — coupled with the North Bay company’s proprietary software — have been used underground for everything from surveying shafts to inspecting drifts to assisting in mine rescue operations.

But the real value of their services, he said, is in the data they collect to help mining operations boost efficiency and safety.

“We’ve evolved from a product company to a company with purpose,” said Campigotto, SafeSight’s co-founder and president.

“And our purpose is collecting high-risk data underground in mining to make it not only more effectively operated, but safer for the workers.”

Their efforts are getting noticed.

In December, SafeSight received close to $600,000 from the federal government to help push two new projects closer to commercialization.

The first is a multi-faceted digital platform that aids mine rescue teams in responding to underground rescue or recovery scenarios.

SafeScout, a small drone that can be flown in to inspect an emergency situation from a safe distance, takes high-definition video of the scene and captures peak air quality readings.

The Deep Traxx fire response vehicle, which resembles a small, remote-controlled monster truck, can be sent to the site of an underground fire and remotely spray a curtain of water to help extinguish flame and tamp down heat.

This is especially valuable as the industry starts adopting battery-electric vehicles underground.

“If they catch fire, the batteries go into thermal runaway — they burn at 5,000 degrees Celsius,” Campigotto said.

“And there’s no way for the current technology to approach them in any way to reduce the heat or provide a safe water curtain for first responders to navigate around or by.”

Because DeepTraxx is 5G-enabled, as long as the mine has 5G capabilities, whatever’s happening in an active response can be livestreamed to surface where those in the command centre can see exactly what the responders are seeing.

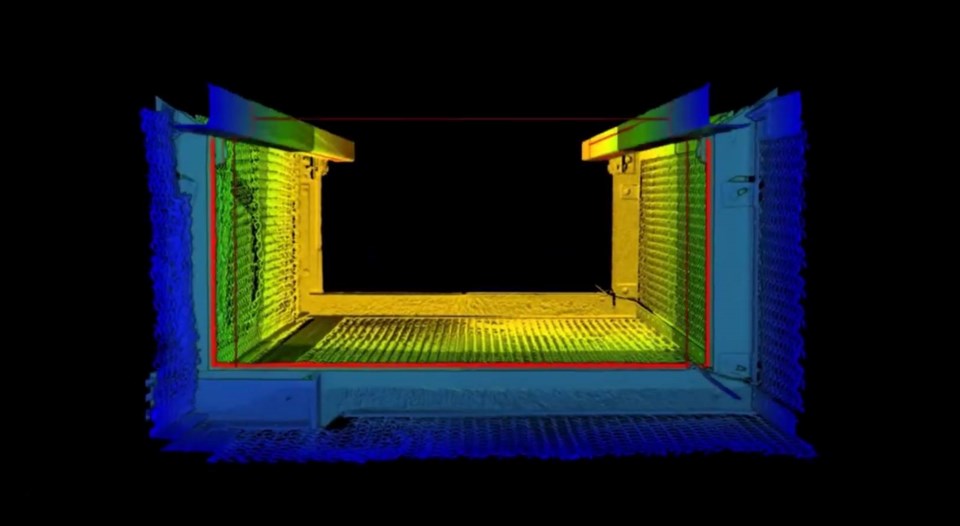

SafeScanner, the company’s scanning and mapping technology, scans a 3D image of the site remotely.

“So responders can now look at a 3D model before they try and determine who to rescue and who to recover,” Campigotto said.

“And if you blend that with the thermal vision, which is high-definition thermal vision, you now get a heat signature of where people are, where the hot spots are.

“Combine that with a 3D geostructural map of the incident, they now have a very deep understanding of what’s going on, they can create a safer, more effective rescue or recovery plan, and move forward.”

The final component is the Rescue Wheel, which clamps onto a rescue basket, enabling the team to help move the injured more quickly to safety.

Want more business news from the North? Subscribe to our newsletter.

SafeSight was recognized for its efforts last May as the winner of the inaugural Mining Technology Innovation Challenge, jointly sponsored by Rogers Communication, Dell, NORCAT, and the Centre for Excellence in Mining Innovation.

The initiative challenged Canadian tech startups to find new applications for 5G in mining that would improve safety, productivity, energy efficiency, and environmental impact.

As the winners, the company will demonstrate the platform’s capabilities during a live simulation of an emergency response at the NORCAT Underground Centre in Onaping on Jan. 24.

SafeSight’s newest offering is shaft measurement technology, which was a two-year collaboration with Vale in Sudbury.

Using light-detecting and ranging (LiDAR), SafeSight’s technology captures a full 3D model of the shaft that’s accurate to within a millimetre.

The process takes about two hours and can be done without interruption to shaft operations, with the software producing both the digital map and the accompanying reports.

Ontario legislation dictates that shaft inspections are required annually, Campigotto said. But the more frequently they’re done, the more effectively a shaft operates, and the less likely production is unexpectedly interrupted.

“The shaft is the carotid artery of the mine in that, that’s how material comes up, and that’s how people come up and down,” he said. “So any interruption to that has a dramatic impact on the productivity and profitability of the site.”

SafeSight offers it as a service, or companies can buy the hardware and software and perform the inspections with their own staff.

As the company grows, the 13-member team is on the hunt to add more staff members.

Campigotto said SafeSight is already short four people and he wants to add another seven to bring its complement to 24.

But the company has been challenged to recruit people locally who have the specialized skill set it needs, even hiring people who are working remotely.

To that end, they’ve recently hired a Toronto firm to streamline their recruiting process, part of which includes establishing summer student and co-operative learning employment opportunities with postsecondary schools in North Bay and Sudbury.

“Their goal is to help us put the infrastructure in place to create a constant flow of opportunity for graduates, undergrads, and high school students so that we can start to indoctrinate them into our culture and into the technology space we’re working in,” Campigotto said.

Next on the horizon, the company is eyeing export opportunities; in particular, to Mexico and South America.

Foreign markets seem more open to jumping into digitized mining than their Canadian counterparts, he said, and are eager to adopt new technology.

Though the company is just at the cusp of this work, Campigotto said they’ve already had what amounts to a crash course in exporting outside the country.

“We’re learning some valuable lessons and really getting an education on the realities of getting technology across borders,” he said.

“To me, I’ve been quite surprised at the amount of time it really takes.”